- #HEAT EXCHANGER CALCULATION SOFTWARE TRIAL SECTOR AND#

- #HEAT EXCHANGER CALCULATION SOFTWARE FREE HEAT EXCHANGER#

- #HEAT EXCHANGER CALCULATION SOFTWARE DOWNLOAD HEAT EXCHANGER#

Software is presented as a simple calculation of a heat exchanger for heating.Read on for information about the use of a heat exchanger design thermal design calculations spreadsheet for a double pipe heat exchanger. Where: P heat load (btu/h) m mass flow rate (lb/h) c p specific heat (btu/lb ☏) t temperature difference between inlet and outlet on one side (☏) k heat transfer coefficient (btu/ft 2 h ☏)Calculate yourself: online form for calculating the water/water exchanger. Heat load, Theta and LMTD calculation. The heat load of a heat exchanger can be derived from the following two formulas: 1.

Heat Exchanger Calculation Software Download Heat Exchanger

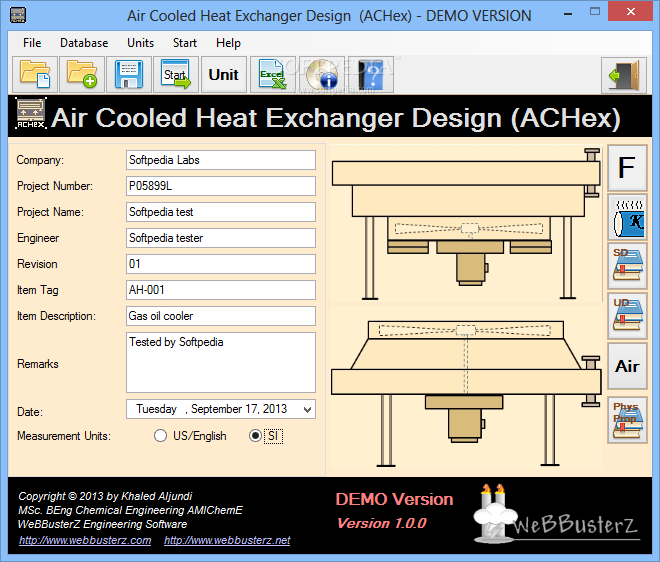

Double Pipe Heat Exchanger Design (DHex) v.1.0 DHex is a software tool that is made to demonstrate the chemical design calculations of Double pipe (hairpin) Heat Exchangers.The software will do all the thermal calculations involved in the design and will generate a summary of all results.etc. Heat exchangersDownload Heat Exchanger Calculation Software. Many heat transfer textbooks e. Thus some type of average temperature difference is needed. The software handles for example single-phase, condenser, evaporator.For heat exchangers, there are always two fluids involved, and the temperatures of both are changing as they pass through the heat exchanger. The driving force for a heat transfer process is always a temperature difference.Double Pipe Heat Exchanger Design(DHex) - software tool for determining chemical design calculations of double pipe (hairpin) heat exchangers, from WeBBusterZ Engineering Energy2D - interactive, visual multiphysics simulation program that models all 3 modes of heat transfer-conduction, convection, radiationSSP is our unique software developed for advanced heat exchange calculations.

The overall heat transfer coefficient, U, depends on the convection coefficient inside the pipe or tube, the convection coefficient on the outside of the pipe or tube, and the thermal conductivity of the pipe wall.See the article, Forced Convection Heat Transfer Coefficient Calculationsfor information about calculating the heat transfer coefficients and click here to visit our spreadsheet storefor spreadsheets to calculate the inside and outside convection coefficients and to calculate the overall heat transfer coefficient.The screenshot below shows a heat exchanger thermal design calculations spreadsheet that can be used to carry out thermal design of a double pipe heat exchanger. The heat transfer rate, Q, can be calculated in a preliminary heat exchanger design spreadsheet if the flow rate, heat capacity and temperature change are known for either the hot fluid or the cold fluid.Then one unknown parameter can be calculated for the other fluid. The equation to be used is shown below for both the hot fluid and the cold fluid. The meanings of the four temperatures in the log mean temperature difference equation are rather self explanatory as shown in the diagram of a counterflow double pipe heat exchanger at the right. FREE Heat Exchanger Design Software HExTemp light - Developed by German engineers - Start in just a few minutesThe definition of the log mean temperature difference is shown in the figure above.

Heat Exchanger Calculation Software Free Heat Exchanger

I use your free heat exchanger software for my lecture. Leave a Reply Cancel reply You must be logged in to post a comment.Your data is safe with us and will be treated confidentially. The Overall Heat Transfer Coefficient, U, for a Heat Exchanger Design Spreadsheet The overall heat transfer coefficient, U, depends on the convection coefficient inside the pipe or tube, the convection coefficient on the outside of the pipe or tube, and the thermal conductivity of the pipe wall.A Heat Exchanger Thermal Design Calculations Spreadsheet The screenshot below shows a heat exchanger thermal design calculations spreadsheet that can be used to carry out thermal design of a double pipe heat exchanger.References 1. You must be logged in to post a comment. The rest of the spreadsheet will calculate the length of pipe needed, the length of each pass for a selected number of degree bends, and the pressure drop through the inside of the pipe.Why bother to make these calculations by hand? This Excel spreadsheet is available in either U.

Thank you very much for the great free heat exchanger software in Excel. Thus one can "play around" with these parameters and get a good feeling on their affect. Particularly interesting is that it very quickly gets the temperature profiles by changing the parameters. I really like your free heat exchanger program in Excel.In my lectures, it helps me to explain heat exchangers to the students in a more visible way. I use your "professional version" to explain the design of tubular heat exchangers to my students.

I am happy to utilize your services for future projects again. With your help and patience, we made a major step forward in the dimensioning and design of a new heat exchanger type. That was very helpful and easy and saved us a lot of money.

Home Connect About us Software Shop. Everyone was happy and I now have a better understanding of the heat exchangers processes. This was confirmed after the installation.

Heat Exchanger Calculation Software Trial Sector And

It includes provision for dumping excess heat to the distribution system, as well as provision for heat recovery during a cool-down cycle Glass Shutters may be used as an alternative to double glazing where it is required to preserve the appearance of your traditional sash windows. Bangalore rowdy kalapatharThis website uses cookies.Software tool for fast and high-quality thermal energy audits and design of energy-efficient heat and cold supply systems in the industrial sector and other large applications.The wood fired boiler system utilizes hot water thermal storage and indirect heating of domestic hot water during firing. Selection between counterflow and coflow. Calculate heat transfer.Easy to use.

Xsimula FEA Solves 2D heat transfer problem in multiple materials with linear or non-linear properties. The program has inside already several fluids for which are calculated the phisical characteristics as conductivity, heat capacity, density, viscosity and latent heat Xsimula FEA is a thermal modelling heat transfer program. The software, developed in visual basic 6, has the capability to input design and actual operating data and compute the water fouling base on meccanical and physical data of the exchanger.The program can bu used for coolers, condensers and exaust steam condenser. Heat exchangers performance monitoring in industrial plants. By choosing an appropriate style, the panel divisions can be made Do you have a GitHub project? Now you can sync your releases automatically with SourceForge and take advantage of both platforms.

COSTER organizes equipment into purchased and fabricated components and groups identical pieces into convenient lists.It estimates labor using a cost factor system that can be adjusted to suit your shop practices. This saves time and enhances collaboration between Mechanical and Thermal Designers. Are you looking for a way to quickly create heat exchanger drawings? Shell roll-outs with nozzle openings, nozzle schedules, nozzle detail drawings, nozzle cut lists, U-tube bend schedules, bills of materials and more are created faster and with fewer mistakes. Design Heat ExchangerHighlights include. It will be a study aid and shall be able to give te relimnary dessign to an expert before he starts and puts his expertise into it.Up to eight design conditions can be investigated for fixed, u-tube, kettle and floating tubesheet style exchangers.Both horizontal and vertical heat exchangers can be modeled. The project targets the chemical engg.

Appendix A tube-to-tubesheet joint calculations. Appendix 26 bellows expansion joints. Tube bundle removal pulling force analysis.Appendix 5 flanged and flued expansion joints.

0 kommentar(er)

0 kommentar(er)